A bearing is a mechanical component that supports and reduces the friction between moving parts, typically in the form of a rolling-element bearing. Ball Bearing numbers typically are represented by a series of numbers and/or letters. These alphanumeric codes indicate specific dimensions, tolerances, and other features of the bearing, allowing for easy identification and selection.

When referring to bearing numbers, we usually mean the bearing designation or part number. This is a standardized alphanumerical code that conveys essential information about the ball bearing, such as type, size, and tolerances.

The most commonly used bearing numbering system is the ISO (International Organization for Standardization) bearing designation system, which is widely followed by manufacturers worldwide. In this system, each bearing number is made up of a combination of letters and numbers that provide specific details about the ball bearing. However, an ABMA (American Bearing Manufacturers Association) numbering system is sometimes used.

Why Understanding Bearing Number Nomenclature is Important

When designing a piece of equipment, you need to determine the correct bearing to use for machine efficiency and smoothness of operation. Load and speed are often major considerations.

When replacing a worn out or broken bearing, understanding the bearing numbering nomenclature is vital to make sure the bearing used will handle load, speed, thrust and other considerations. An improper ball bearing can cause premature failure, and potentially unsafe operation.

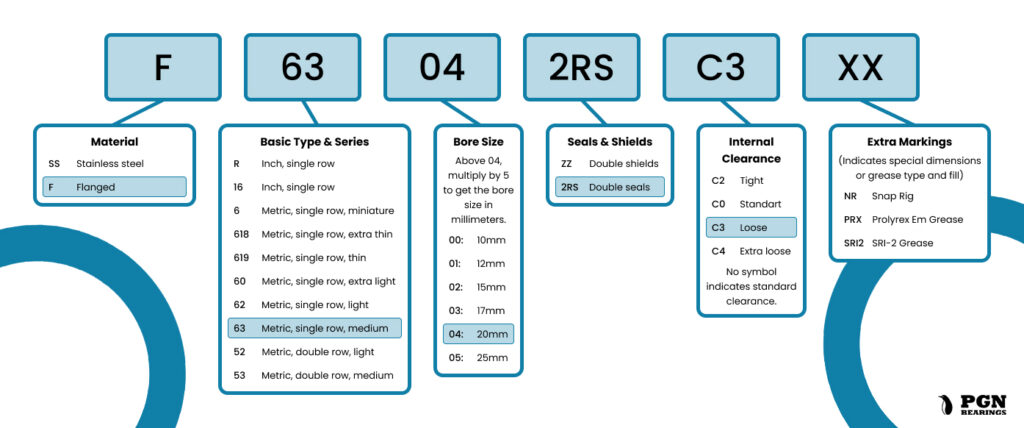

Here’s a breakdown of the ISO bearing designation system with examples:

- Bearing Type (Prefix): This is usually represented by letters that indicate the type or style of bearing. Note that the Prefix may vary from manufacturer to manufacturer. Please consult crossover/interchange charts and other documentation to get an exact replacement. Example:

- “N” – Single row no flanges on outer ring

- “NU” – for Single-row, no flanges on inner ring

- “NJ” – Single-row cylindrical roller bearing with one flange on the inner ring

- “HJ” – Stabilizing ring

- Bearing Series: This is a number that stands for the bearing’s dimensional series, which is based on certain dimensions and load ratings. Example:

- “X2” for Light series

- “X3” for Medium series

- “X4” for Heavy series

Where “X” indicates the bearing type. For example, 6 would be a single row, deep groove ball bearing.

- Bearing Bore Size: This normally is a two-digit number standing for the bearing’s bore diameter in millimeters, often multiplied by 5. It is the last 2 digits in the 4 digit bearing main number. Example:

- “08” indicates a bore diameter of 40mm (8 x 5 = 40)

- “12” indicates a bore diameter of 60mm (12 x 5 = 60)

- Additional Designations (Suffixes): These letters or numbers indicate any specific features or variations of the bearing, such as clearance, seals, or material. Example:

- “C3” for Radial internal clearance greater than normal

- “2RS” for Rubber seals on both sides of the bearing

- “TVP” for Polyamide (plastic) cage

Remember that while both prefixes and suffixes can be similar, many bearing manufactures use their own designations to indicate special options, such as cage type, seal type and material, and specialty construction features.

Examples of Ball Bearing Numbers

Bearing numbers are included on the packaging container and usually include both the prefix and suffix if required. The simple or main bearing number will also be etched or stamped on the inner ring of the bearing. It may or may not include any additional bearing nomenclatures.

Let’s look at some examples of bearing numbers:

Example 1: 6205

- “6” indicates the bearing type, which in this case is a single-row deep groove ball bearing.

- “2” is the series, referring to the light series in the 62xx range of bearings.

- “05” represents the bore size, which is 5mm multiplied by the last two digits (5 x 5 = 25mm).

Example 2: 6308-2RS

- “6” again indicates a single-row deep groove ball bearing.

- “3” is the series, referring to the medium series in the 63xx range of bearings.

- “08” represents the bore size, which is 5mm multiplied by the last two digits (5 x 8 = 40mm).

- “2RS” is a suffix that indicates the bearing has two rubber seals (RS = Rubber Seal) on both sides of the bearing to protect it from contaminants and retain lubricant.

Example 3: 7206 B

- “7” indicates the bearing type, which in this case is a single-row angular contact ball bearing.

- “2” is the series, referring to the light series in the 72xx range of bearings.

- “06” represents the bore size, which is 5mm multiplied by the last two digits (5 x 6 = 30mm).

- “B” is a suffix that indicates the bearing has a 40-degree contact angle.

Please note that there are many different ball bearing types, series, and suffixes. This is just a general overview, and specific bearings may have unique numbering systems depending on the manufacturer and application.

Sample Chart of Bore Diameters

The 6200 series is a family of single-row deep groove ball bearings. The four-digit bearing number usually represents the type, series, and bore size.

In the case of the 6200 series, the first digit “6” indicates a single-row deep groove ball bearing, and the second digit “2” refers to the 62xx range of bearings. The last two digits represent the bore size, which is 5 times the last two digits.

This chart shows some data for bore dimensions for various ball bearings in the 6200 series. Note that bore dimensions are given in millimeters.

For final digits 00 through 03, consult the chart for their bore diameters as indicated. For digits 04 and above, multiply the last two digits by 5 to get the inner bore diameter.

Bearing Numbering Systems – Summing It All Up

Understanding bearing number systems is crucial for designers and maintenance personnel. The efficiency, performance, and reliability of machines and equipment rely immensely on the proper selection and maintenance of bearings. By understanding bearing number systems, these professionals can ensure compatibility and performance in a wide range of applications.

For designers, knowledge of bearing number systems allows for the accurate selection and specification of bearings, tailored to the specific requirements of a given project. This not only guarantees the proper fit and function of components, but also helps minimize design errors. It can also reduce production costs, and ensure a longer lifespan for the product.

For maintenance personnel, understanding bearing number systems is essential for accurate identification, diagnosis, and replacement of damaged or worn-out ball bearings. This knowledge helps them maintain facility machinery in peak operating condition, minimizing downtime and reducing the risk of catastrophic failures.

In the constantly evolving world of engineering and machine maintenance, understanding bearing number systems is a skill that benefits both professionals and the machinery they work with. By staying up to date with industry standards and advancements, designers and maintenance personnel can ensure a more dependable, efficient, and profitable future for their organizations.